| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | POTENTIAL / POTENCY |

| Model Number : | KMZ611 |

| Certification : | ISO9001:2015 |

| Price : | Negotiable |

| Delivery Time : | 45 working days |

| Payment Terms : | T/T, L/C |

| Supply Ability : | 120 units per year |

Drilling Anchoring Grouting Equipment KMZ611 Advanced Solution with Grouting Flow of 2500l/h and Rock Drill Power of 16.5Kw

The Potential/Potency KMZ611 Anchor Injection Trolley is a

specialized piece of equipment developed for underground hydropower

engineering. This advanced trolley is designed to integrate a range

of functions, including hydraulic rock drilling, anchor rod

installation, grouting, and mesh installation, all in one

convenient package. It offers versatility in its usage, including

tunnel support in water diversion projects, railways, highways,

deep foundation pits in high-rise buildings, and support operations

in underground hydroelectric power plants.

Prior to the introduction of this innovative device, the field of

water conservancy and hydropower lacked any significant mechanized

construction equipment. The Potential/Potency KMZ611 Anchor

Injection Trolley has effectively filled this gap, providing a

much-needed solution to many of the complex challenges inherent in

underground hydropower engineering.

Whether you're working on a complex underground hydropower project

or looking for a versatile piece of equipment for other operations,

the Potential/Potency KMZ611 Anchor Injection Trolley is the

perfect solution. Its advanced features, efficient design and

unparalleled functionality make it the ideal choice for any job

that requires precision, flexibility and power.

Chassis Form: The vehicle has an engineering chassis that is equipped with

four-wheel drive and four-wheel steering to ensure maximum

maneuverability and stability on any terrain.

Power: The vehicle runs on a dual power system that uses both diesel and

electric power sources. This provides not only greater fuel

efficiency, but also increased flexibility and performance for a

wider range of work environments.

Control System: The vehicle has a state-of-the-art controller control system that

allows for precise and efficient operation. The system also

includes a parameter large screen display that provides real-time

data on various aspects of the vehicle's performance, including

fuel consumption and operating status. In addition, there is an arm

control intelligent assistance system that provides automated

assistance to the operator during operation.

Arm Capabilities: The vehicle's main arm integrates hydraulic rock drilling,

drilling system, grouting system, and anchor rod installation

system. This allows for efficient and simultaneous drilling and

installation of anchor rods while eliminating the need for separate

equipment. Meanwhile, the auxiliary arm features a high-altitude

work platform mounted on a fully hydraulic multi degree of freedom

robotic arm. This allows for safe and efficient access to

hard-to-reach areas while providing full control and

maneuverability for the operator.

Here is a table with various parameters and their respective values and units:

| Item | Parameter | Value | Unit |

|---|---|---|---|

| 1 | Weight | 25500 | kg |

| 2 | Walking Speed | 0~15 | km/h |

| 3 | Rock Drill Power | 16.5 | kw |

| 4 | Drilling Diameter of Rock Drill | Φ43~Φ76 | mm |

| 5 | Drilling Depth of Rock Drill (Single Rod) | 6 | m |

| 6 | Drilling Speed of Rock Drill | 1-1.2 | m/min |

| 7 | Water-cooled Diesel Engine | 119/2200 | kw/rpm |

| 8 | Minimum Turning Radius | Inner≤3.4m;Outer≤8.5m | m |

| 9 | Gradeability | 15 | ° |

| 10 | Theoretical Maximum Flow Rate of Grouting System | 2500 | l/h |

| 11 | Maximum Working Height | 11 | m |

| 12 | Maximum Working Width | 11 | m |

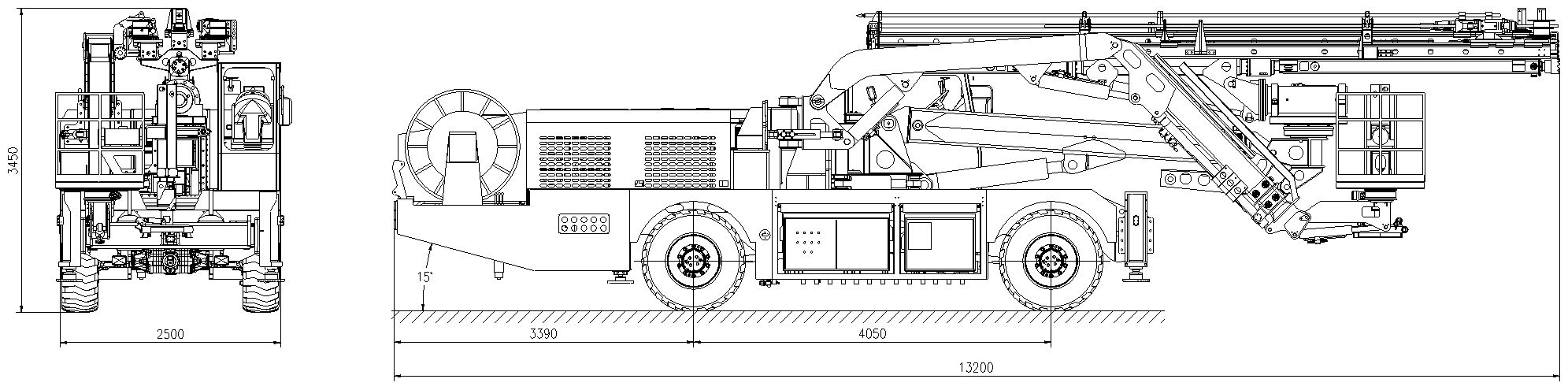

| 13 | Dimensions in Transport State (Length x Width x Height) | 13200*2500*3450 | mm |

| 14 | Air Compressor Power | 3.6 | kw |

The table above provides information on various parameters and

their values and units. Some of these parameters describe the

technical specifications of a machine or equipment. For example,

the weight of the machine is 25500 kilograms. The walking speed of

the machine ranges from 0 to 15 kilometers per hour. The power of

the rock drill is 16.5 kilowatts, and the drilling diameter of the

rock drill is between Φ43 and Φ76 millimeters. The machine is

capable of drilling up to 6 meters in depth with a single rod, and

the drilling speed of the rock drill is 1 to 1.2 meters per minute.

Additionally, the machine comes equipped with a water-cooled diesel

engine that provides 119/2200 kilowatts/rpm.

The minimum turning radius of the machine is less than or equal to

3.4 meters for the inner radius and less than or equal to 8.5

meters for the outer radius. The gradeability of the machine is 15

degrees, and the theoretical maximum flow rate of the grouting

system is 2500 liters per hour. The maximum working height and

width of the machine are both 11 meters. The machine's dimensions

in transport state, measured in length by width by height, are

13200 by 2500 by 3450 millimeters. Finally, the air compressor

power of the machine is 3.6 kilowatts.

Tunnel engineering utilizes water and electricity anchor rod

trolleys for support operations during tunnel excavation. The

stability of surrounding rock must be ensured during tunnel

excavation through support mechanisms. Efficiently performing tasks

such as drilling anchor rods, automatic clamping and pushing anchor

rods, and automatic grouting, the anchor rod trolleys improve the

speed and quality of tunnel excavation.

In the realm of underground engineering, water and electricity

anchor rod trolleys have become essential equipment in scenarios

such as underground factory excavation, subway construction, water

conservancy engineering, underground pipe galleries and other

similar construction projects. The implementation of these projects

requires significant attention towards reinforcement of tunnels,

installation of supports, and installation of protective walls to

ensure the structures' stability and safety. The anchor rod trolley

is a valuable asset in these projects as it can easily and quickly

complete the tasks, improving the construction's quality and

promoting overall work safety.

The Drilling Anchoring Grouting Equipment product comes with a

comprehensive technical support and service package to ensure that

our customers are satisfied with their purchase. Our team of

experienced technicians and engineers are available to provide

assistance throughout the entire product lifecycle, from

installation to maintenance and repair.

We offer a range of services including:

At Drilling Anchoring Grouting Equipment, we are committed to

providing our customers with the highest level of support and

service. Contact us today to learn more about how we can help you

get the most out of your equipment.

|