| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | POTENTIAL / POTENCY |

| Model Number : | KMZ5012 |

| Certification : | ISO9001:2015 |

| Price : | Negotiable |

| Payment Terms : | T/T, L/C |

| Supply Ability : | 120 Units Per Year |

| Delivery Time : | 45 Working Days |

KMZ5012 Top-Performing Drilling Anchoring Grouting Equipment for Superior Construction Results

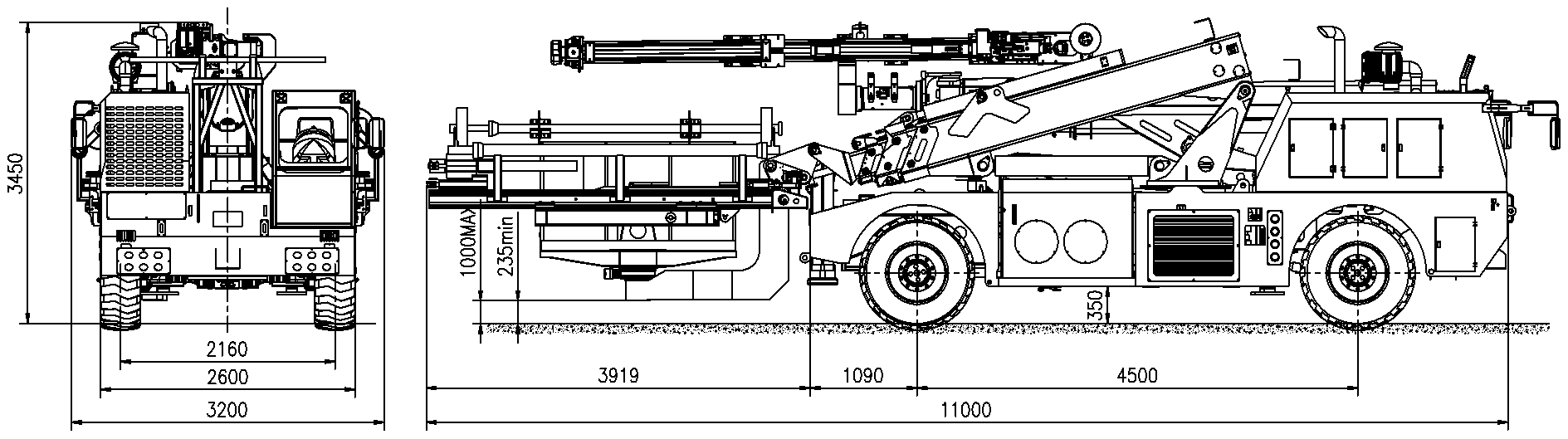

Potential/Potency KMZ5012 is a multifunctional drilling and anchoring trolley developed for tunnel construction. It can handle drilling, anchoring, and grouting operations for expansion shell anchor rods, resin anchor rods, and single strand anchor rods. It is also the first equipment in China to achieve parallel drilling and anchoring operations.

1. Engineering chassis, four-wheel drive, strong climbing ability;

Four wheel steering with a small turning radius;

2. Three working arm frame; The middle arm is a rock drilling arm,

and the left and right arms are anchor rod installation arms;

3. Controller control, parameter display on large screen, real-time

monitoring of system operation status;

4. The intelligent assistance system for controlling the n-arm can

achieve one click automatic matching of drill rod and anchor rod

orientation, improving efficiency.

| Item | Parameter | Value | Unit |

| 1 | Weight | 29500 | kg |

| 2 | Ground Clearance | 480 | mm |

| 3 | Rock Drill Power | 22 | kw |

| 4 | Max. Drilling Diameter of Rock Drill | Φ115 | mm |

| 5 | Drilling Depth of Rock Drill (Single Rod) | 5 ( Single Pole ) | m |

| 6 | Drilling Speed of Rock Drill | 1-1.2 | m/min |

| 7 | Water-cooled Diesel Engine | 129/2200 | kw/rpm |

| 8 | Minimum Turning Radius | Inner≤2.5m;Outer≤8.5m | m |

| 9 | Gradeability | 20 | ° |

| 10 | Theoretical Maximum Flow Rate of Grouting System | 1200 | l/h |

| 11 |

| 12 | m |

| 12 | Maximum Working Width | 15 | m |

| 13 | Dimensions in Transport State (Length x Width x Height) | 11600*3200*3450 | mm |

| 14 | Air Compressor Power | 7 | kw |

Our KMZ 5012 install anchor rods/cables through the end working

devices of the left and right arm frames:

Step 1: Use the remote control to quickly deploy the boom to the

vicinity of the anchor hole;

Step 2: Manually place resin or cement coil anchoring agent into

the bottom of the hole through a PVC pipe station on the platform;

Step 3: Use the remote control to select the hole position where

the anchor rod needs to be installed;

After selection, the working device will automatically and quickly

adjust its posture to align with the anchor

The orientation of the rod hole is consistent and locked. Step 4:

Use the remote control to install the anchor rod into the friction

wheel;

Step 5: Adjust (micro move) the arm movement through the remote

control to align the anchor rod with the anchor rod hole;

Step 6: The anchor rod is fed in through the friction wheel until

it comes into contact with the anchoring agent (which can be

determined by the length of the exposed anchor rod);

Step 7: Anchor rod device in place;

Step 8: Push the anchor rod device forward until the anchor rod is

inserted into the bottom of the hole and fix the anchor head;

(Resin and cement medicine roll anchoring agent need to be pushed

while rotating)

Step 9: Install the exhaust pipe and seal the hole opening;

(Manually operated on the platform)

Step 10: Apply prestress; (By applying torque through the anchor

rod device torque tube, the torque can be set on the control panel

of the electrical control cabinet)

Step 11: Grouting and sealing~~

|